This is the third part of our article series, which follows the collaborative project between Restaurant Nolla, Muoviamo, and TELMA students from Live Vocational College.

At the heart of the project is the transformation of plastic waste accumulated at Restaurant Nolla into new, functional items suitable for restaurant use. In the first part of the series, we introduced the project’s background, and in the second part, we covered the design workshop with TELMA students, where initial ideas for new cutlery rests were created.

Muoviamo’s Mobile Plastic Laboratory

Next, it was the turn of Restaurant Nolla’s staff to get concretely involved in the process. The workshop was held at Muoviamo’s own unique plastic workshop. The workshop is built into a former food-grade semi-trailer, and we call it the “plastic lab.”

Muoviamo’s mobile Plastic Lab. Designed to travel where needed. You can even book the lab for your own event! IMAGE: Muoviamo

This mobile laboratory is equipped with all the necessary machinery for processing plastic from waste into finished art or utility items. The lab’s equipment includes, among other things, an injection press, a shredder, heat presses, and an extruder. The workshop offered Nolla’s staff a deep, hands-on experience of the plastic’s journey.

Joint design for form and function

At the beginning of the workshop, we took a closer look at the clay models of cutlery rests created by the TELMA students from Live Vocational College in the previous workshop. These models served as a valuable starting point, and by examining them, we could evaluate the strengths and weaknesses of different shapes and sizes. Based on the students’ ideas, important aspects were decided upon, such as the suitable size and form of the cutlery rest for Nolla’s purposes.

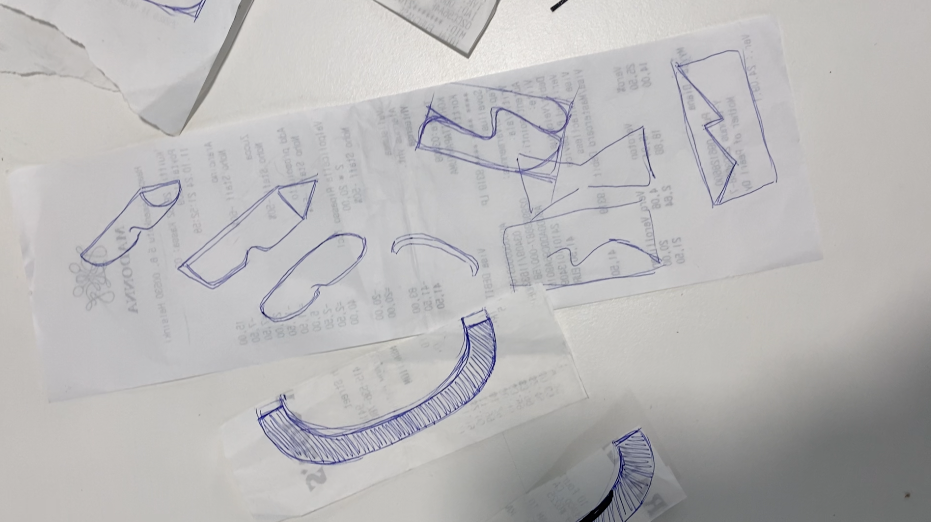

Restaurant Nolla’s staff also had the opportunity during the workshop to design their own ideas and wishes for the future cutlery rest. Based on this joint design process and the foundation provided by the students’ models, Muoviamo later proceeded to design the final cutlery rest model. The final model will remain a secret until the end of this article series!

Ideating cutlery rest designs. IMAGE: Muoviamo

Nolla’s team shared their design ideas and wishes for the cutlery rest. IMAGE: Muoviamo

Plastic’s journey from waste to raw material – getting hands dirty

A key part of Nolla’s workshop was getting acquainted with the plastic processing workflow from start to finish. The Nolla team brought plastic waste collected at the restaurant, all of which is food-grade PP5 and HDPE plastic. In the workshop, they got to clean the plastics themselves, remove labels, and feed them into the shredder, which ground the plastic into small granules. This provided a concrete understanding of the steps required to recycle plastic into a raw material.

Most of Nolla’s plastic waste consisted of food storage containers. The plastics were cleaned and labels were removed. IMAGE: Muoviamo

Furthermore, different ways of processing plastic were experimented with in the workshop. Participants had the chance, for example, to make various small utility items, such as wallets, from plastic bags they brought with them, using a heat press. This demonstrated in practice how new products can be created from waste plastic even with relatively simple techniques. The workshop day also included a pleasant joint lunch.

Towards the finished product

The project is now moving quickly towards manufacturing. The design ideas from the TELMA students, the feedback and wishes provided by Nolla’s staff, and Muoviamo’s plastic processing expertise are being combined in the final product design. The final cutlery rests will be made specifically from Nolla’s own plastic waste – primarily from PP5 plastic, which was the most abundant material collected at the restaurant and is easy and safe to process.

Stay tuned and follow the final stages of the project! In this article series, we have followed plastic’s journey from waste to design idea and raw material. In the final part, we will reveal what the cutlery rest ultimately became and show how the restaurant’s own plastic waste has been given a new life as tangible utility items.

Visit Nolla

If you are interested in seeing the finished cutlery rests in use or want to explore Restaurant Nolla’s other zero-waste solutions, consider visiting their restaurant at Fredrikinkatu 22, 00120 Helsinki.

Continue to Part 4 of our series.